|

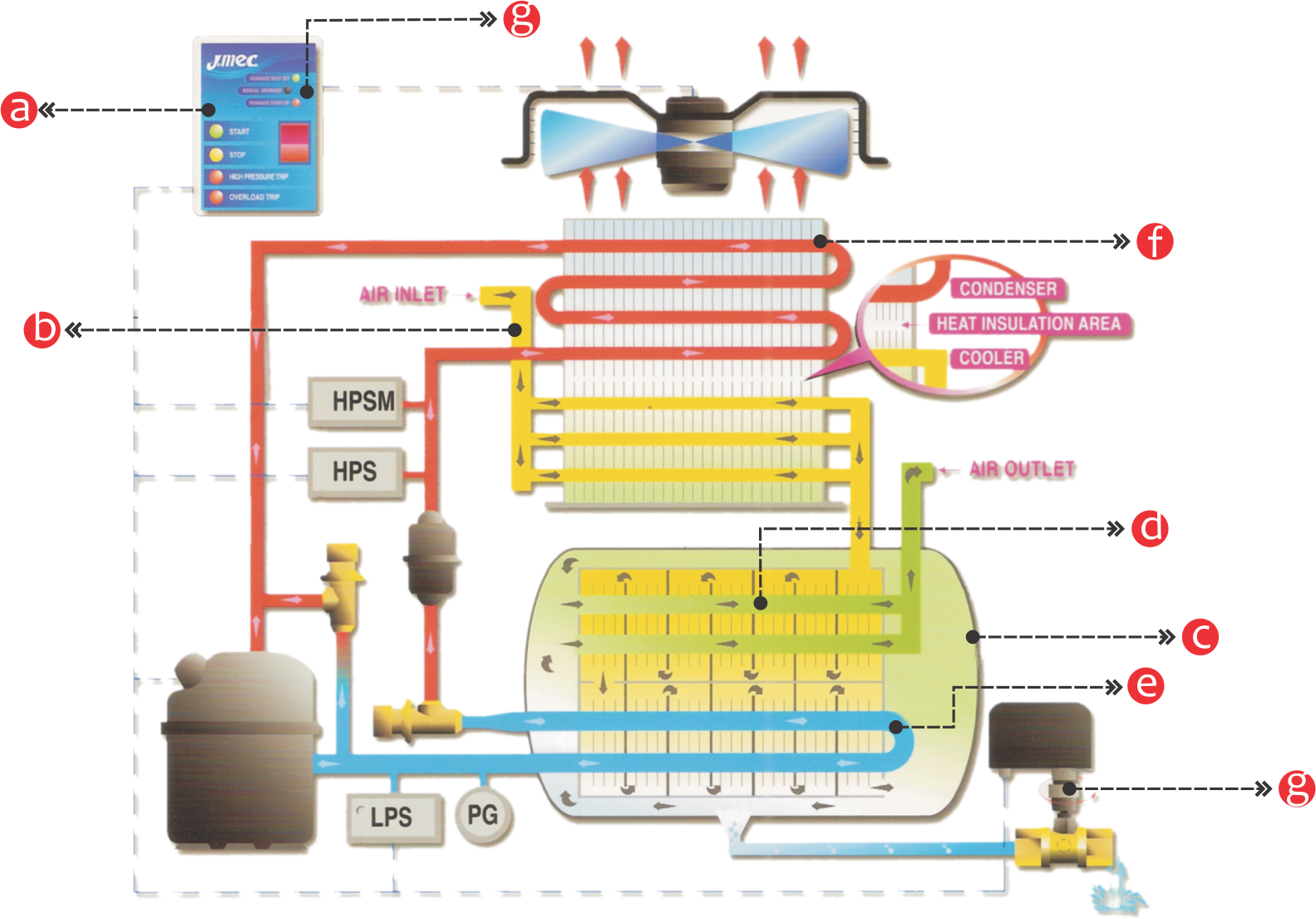

Our Refrigerated Compressed Air Dryer consists of :

a) A completely automatic self contained Logic controller with standard wiring requiring "no adjustments"

b) A "pre-cooler" with excellent air distribution and very low pressure drop, built in the refrigeration condenser coil, with thermal isolation, to cool the incoming compressed air

c) A compact Stainless steel (rust free) high pressure vessel. Two-in-one design containing Air-to-Air heat exchanger and a high efficiency evaporator

d) Air-to-Air Heat Exchanger made out of threaded bronze tubes with aluminium fins and diversion plates plus Reverse Channel design to give better cooling efficiency, higher outlet air temperature and lower energy consumption

e) Evaporator made out of wave type aluminium fins with diversion plates to increase the contact surface of air and refrigerant so as to give optimum cooling efficiency

f) A very large intake condenser with “blow-up” design for better heat rejection and good ventilation and

g) A "motor-driven" (no more burnt solenoid coils) timer controller electronic drainage with anti-blockage large ball valve.

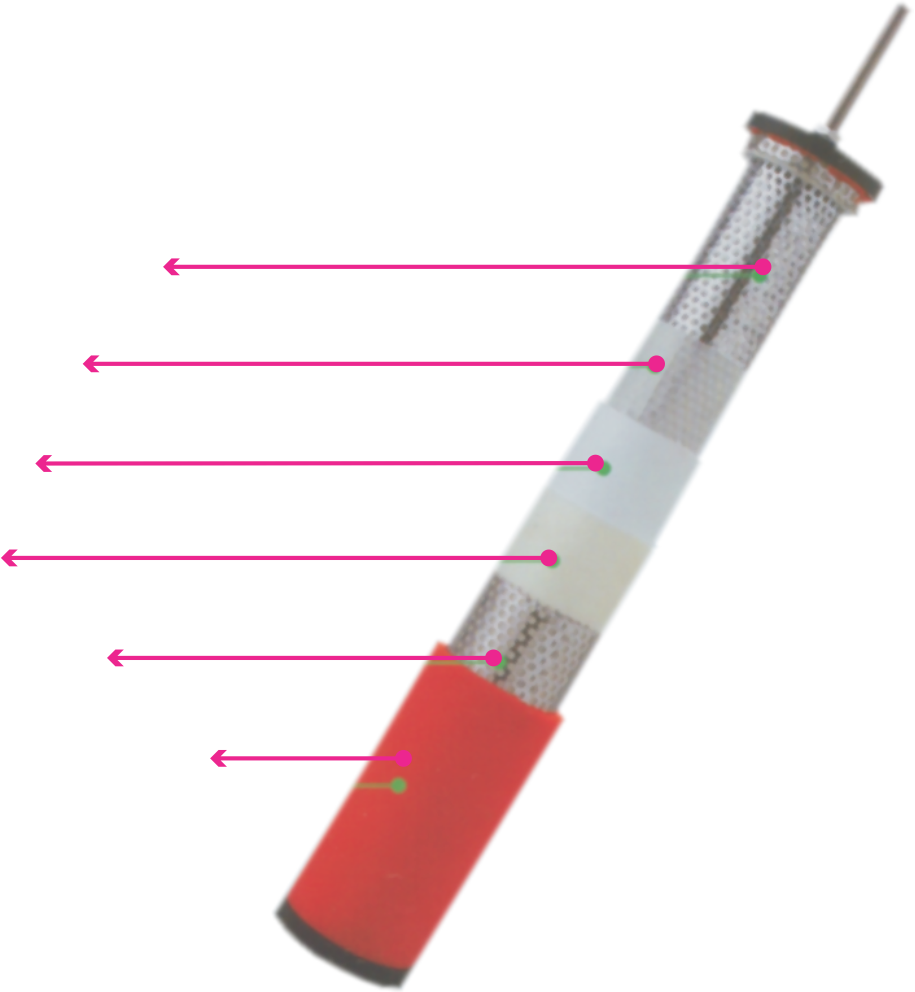

High Efficiency Compressed Air Filter

Differential pressure gauge ensures element in good working condition. Replace element when differential pressure gauge changes to red

Computer-designed air flow path increases contact area for more efficiency and decreased pressure drop

JMF Series - Aluminium alloy die cast impregnated with epoxy resin. High pressure rated to 227psig and corrosion resistant. JML Series - Stainless steel housing (flange excepted) with epoxy coating. High flow rated to 4412 SCFM.

Equipped manual drain or optional auto drain.Internal float drain for grade -15F only

Stainless Steel Support Screen (10µ)

Fine Borosillicate Fiber

Ultra Fine Borosilicate Fiber

Fine Support Borosilicate Fiber

Stainless Steel Support Screen (10µ)

Silicone-Free Anti Re-entrainment Barrier

|