Coolant chillers engineered for machining and tooling

Modern CNC machines involve high spindle speeds and fast material removal rates which generate a lot of heat. This heat is directly added to the cutting fluid/coolant associated during the process. Advance Cooling Coolant Chillers are used to maintain precise coolant temperature by rapidly rejecting the heat which added during the machining process. The chillers are used to operate with water as well oil based coolant fluids.

Salient Features & General Characteristics:

Advance Cooling Chillers are ruggedly designed to work 24 x 7 throughout the year in extremely harsh industrial environment.

Chillers are available in Stand Alone and Dip In type configurations.

Oil based & Water based coolants.

Chillers range from 0.3 to 50 Tr, liquid temp +25to40°C. (Higher temp models available on request)

Self Sufficient Chillers with built in Refrigeration circuit, oil reservoir, transfer pump and necessary controls.

Extra large Sized Condenser Coil and Air Filters for operation in high Ambient up till S0 Deg C.

Plug and Play type fully factory tested ,pre wired charged and piped for easy installation.

Microprocessor-controlled temp controller with digital display, alarms, and secure password. Set point & Differential controls with respect to Ambient / Machine body temperature.

Chiller manufactured in state of art facilities along with ISO 9001: 2015 procedures and thoroughly tested and packaged before dispatching

Chiller designed on latest 3D CAD software to ensure components placed for easy access and compact body footprint.

Configuration :

- Stand Alone Type

- DIP IN /SUBMERSIBLE TYPE

Standalone type chillers consists of an inbuilt pump ,which when energized it draws fluid from the remote coolant tank and pumps it through the evaporator in the chiller and back to the tank. The temperature controller senses the temperature of the fluid entering the chiller and controls the refrigeration effect of the chiller thus ensuring the desired fluid temperature in the tank. The cooler should be installed as near as possible to the tank

Dip in Type Chi 11 er s are

designed to be mounted on top

of a tank to cool the fluid that is passing through it. It has an inbuilt stainless steel

immersion coil type evaporator

which is submerged into the

fluid in the tank. An optional

small agitation pump can be

provided which can continuously moves the fluid around the evaporator coils ensuring uniform heat transfer. The temperature controller senses the temperature of the fluid in the tank and controls the refrigeration effect temperature in the tank DIP IN Chillers are very popular as they save on valuable floor space and are ideal for installation on tanks where the coolant is filled with containments like chips. Muck etc,. The evaporator coils can be periodically cleaned by simply lifting the chiller from the tank

Options:

- Compressors(sealed, semi sealed reciprocatory & scroll).

- Wide selection of Evaporators made up of Stainless Steel tubes: Openable Coil In Shell type, Shell in Shell type, Shell in Tube type, Coil intank type, Gear/ Vane /Trochoid / Centrifugal Pump options

- Air and water cooled Condensers (fin and tube, plate type and shell-in-tube).

- Built in Electrical control box with MCB, Contactors, Thermal Relay/ MPCB / Phase Sequence relay and all status/fault indicating LEDS and audio alarms.

- Safety devices include - high / low refrigerant pressure switches, Anti freeze thermostat, oil pressure and flow switch, inline filter.

- MS/ GI powder coated or stainless steel outer sheet metal body.

- Refrigerant circuit consists of filter dryer, thermostatic expansion valve / capillary, sight glass, accumulator, receiver, solenoid valve, hot gas bypass, Gauges and other controls.

- Optional fan speed controller used for operation of chiller at low ambient.

- RefrigerantR22/R134a/R407c.

- Gear /Vane/Trochoid Pump options.

- State of the Art Digital temperature controller with LED/ LCD for precise temperature controlling.

- Fixed Setpoint or Differential w.r.t ambient temperature control available. Potential free alarm /control signals and interlocks available for Machine-Chiller Interfacing and Remote Signaling. Optional RS 232/ 485 communication is also available

- High Quality Refrigerant grade copper tubing with internal mirror finishing.

- Unit mounted on C Channels orCastorwheelswith lockable brakes for easy movement..

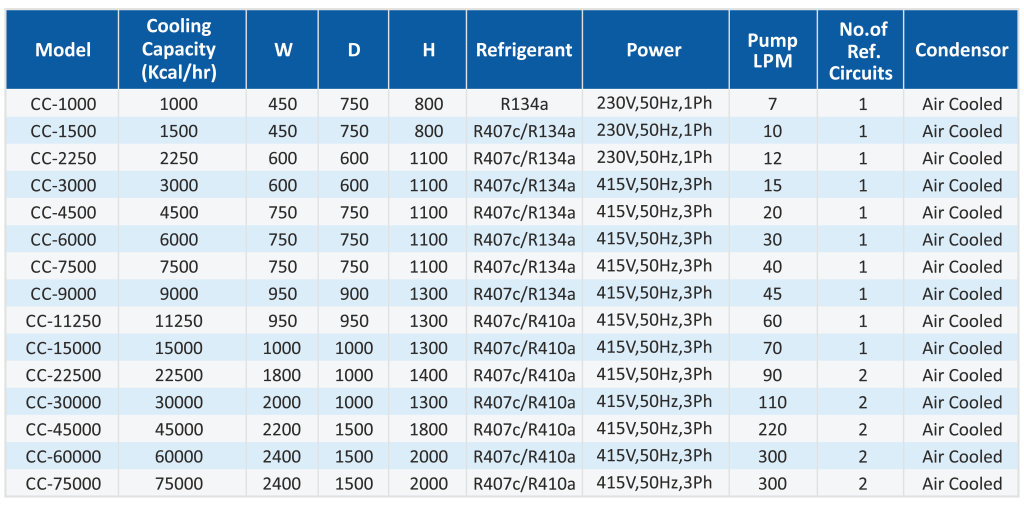

Stand Alone Type Technical specifications

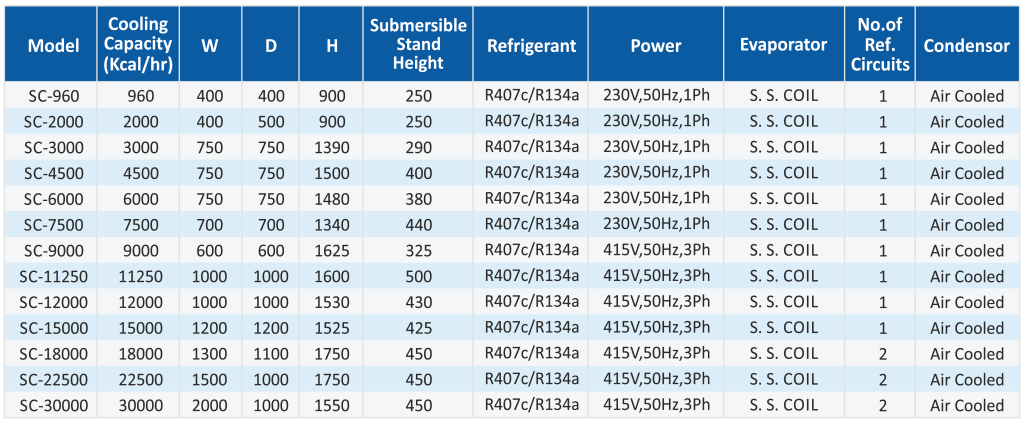

DIP IN /SUBMERSIBLE TYPE Technical specifications

Applications:

- Metal Cutting-Turning, Machining Centers, Grinding, Honing, Broaching , Drilling, Gear Hobbing, Threading etc..

- General Purpose Machining Equipment

Get In Touch

Interested in our product?

Answer a few short questions and we’ll get in touch with you!

Other cooling Solutions

Explore Our Diverse Product Range