Large Capacity Scroll-Screw Water Chillers

- Home

- Liquid Cooling Solutions

- Large Capacity Scroll/Screw Water Chillers

Large-capacity scroll & screw water chillers for heavy industrial processes

Advance Large Capacity Water Chillers are used to provide chilled water at a precise temperature to sensitive water cooled equipment. Designed to work in hostile industrial environment, these chillers are appreciably reducing costs in a broad range of industries. Our Chillers for process cooling and equipment cooling enhance production processes and lower operating costs.

Unlike a cooling tower which may provide adequate cooling during certain months but fail during the hotter months, Advance Water Chillers maintain constant cooling temperature in the equipment right through the year. Unlike water chillers in the market which are for general purpose applications, our chillers come with a focused application design. You therefore get the optimum solution to your heat management problem.

Salient Features & General Characteristics:

Advance Chillers are ruggedly designed to work 24 x 7 throughout the year in extremely harsh industrial environment.

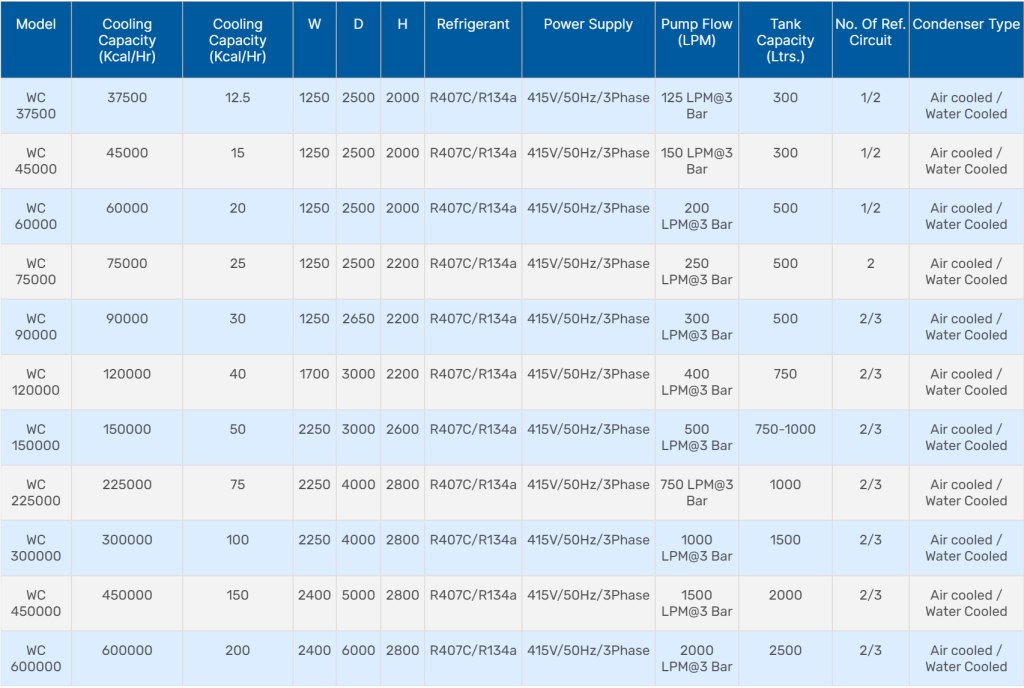

Chillers are available in wide range from 12tr Tr to 200 Tr cooling capacities and liquid temperature range of+5to30 DegC.

Self Sufficient Chillers with built in Refrigeration circuit, water reservoir , transfer pump and necessary controls. For larger capacities, water reservoir can be provided externally

Extra large Sized Condenser Coil and Air Filters for operation in High Ambient up till 50 DegC.

Plug and Play type fully factory tested, pre wired charged and piped for easy installation.

Temperature controller: Microprocessor/PLC-based, LED/LCD display, alarms, user-friendly, secure password feature.

Use of latest energy efficient compressor/Fan/pump.

Chiller manufactured in state of art facilities along with ISO 9001:2015 procedures and thoroughly tested and packaged before dispatching.

Chiller designed on latest 3D CAD software to ensure components placed for easy access and compact body footprint.

Options:

- Compressors (sealed, semi sealed reciprocatory, scroll and screw).

- Evaporators (plate type and shell-in-tube).

- Air and water cooled Condensers (fin and tube, plate type and shell-in-tube).

- Refrigerant Rl34a I R407C ! R410a

- MSI GI powder coated or stainless steel outer sheet metal body.

- inbuilt sufficient fully stainless steel304 I 316 Grade tank reservoir.

- Flow and pressure of Water Transfer pump selection based on application needs.

- Refrigerant circuit consists of filter dryer, thermostatic expansion valve / capillary, sight glass, accumulator, receiver,solenoidvalve, hot gas bypass, Gauges and other controls.

- Unit mounted on C Channels or Castor wheels with lockable brakes for easy movement.

- Optional RS 232 /485 communication is also available.

- Anti corrosive nonferrous parts used for DM Water/ Food grade/ Pharmaceutical/ laser applications.

- Optional fan speed controller used for operation of chiller at low ambient.

- Safety devices include - high I low refrigerant pressure switches Anti freeze thermostat, Water level, pressure and flow switch, in line water filter.

- Built in Electrical control box with MCB, Contactors, Thermal Relay/ MPCB / Phase Sequence relay and all status I fault indicating LEDS and audio alarms.

- State of the Art Digital temperature controller with LED/ LCD forprecise temperature controlling.

- Custom built size for replacement of Imported units and special applications.

- Potential free alarm I control signals and interlocks available for Machine - Chiller Interfacing and Remote Signaling.

- High Quality Refrigerant grade copper tubing with internal mirror finishing.

Technical specifications

Get In Touch

Interested in our product?

Answer a few short questions and we’ll get in touch with you!

Other cooling Solutions

Explore Our Diverse Product Range