Spindle oil chillers for CNC and high-speed spindles

The constant loads and continuous functioning of the spindle in a CNC machine leads to a generation of a lot of heat. For proper functioning and durability of the spindle, it is very essential to remove this excess heat.

Advance Cooling chillers keep the spindle cool so as to control spindle and head growth. These chillers are very essential component of spindles as they add life to the spindle and they are typically used in long cycles or high duty cycles. Advance Cooling has introduced new range of spindle chillers which have a compact footprint and pleasing aesthetics and looks.

Salient Features & General Characteristics:

Advance Cooling Chillers are ruggedly designed to work 24 x 7 throughout the year in extremely harsh industrial environment.

Spindle Chillers range from 0.3 to 2Tr, liquid temp +10 to 45°C.

Self Sufficient Chillers with built in Refrigeration circuit, oil reservoir, transfer pump and necessary controls.

Extra large Sized Condenser Coil and Air Filters for operation in High Ambient up till 50 Deg C.

Plug and Play type fully factory tested ,pre wired charged and piped for easy installation.

Microprocessor-controlled temp controller with digital display, alarms, and secure password.

Set point & Differential controls with respect to Ambient / Machine body temperature.

Chiller manufactured in state of art facilities along with ISO 9001: 2015 procedures and thoroughly tested and packaged before dispatching

Chiller designed on latest 3D CAD software to ensure components placed for easy access and compact body footprint.

Options:

- Compressors ( Reciprocatory & Scroll) Rotary.

- Evaporators (Compact Brazed Plate Type, Coil in Shell Type) Pump Gear /Vane /Trochoid Pump options.

- Air and water cooled Condensers (fin and tube, plate type and shell-in-tube).

- Built in Electrical control box with MCB, Contactors, Thermal Relay/ MPCB / Phase Sequence relay and all status/fault indicating LEDS and audio alarms.

- Safety devices include - high / low refrigerant pressure switches, Anti freeze thermostat, oil pressure and flow switch, inline filter.

- Refrigerant circuit consists of filter dryer, thermostatic expansion valve / capillary, sight glass, accumulator, receiver, solenoid valve, hot gas bypass, Gauges and other controls.

- Refrigerant R134a/R407c/R410a.

- MS/ GI powder coated or stainless steel outer sheet metal body.

- State of the Art Digital temperature controller with LED/ LCD for precise temperature controlling. Set point & Differential controls.

- Potential free alarm / control signals and interlocks available for Machine - Chiller Interfacing and Remote Signalling. Optional Rs232/ 485communication is also available

- High Quality Refrigerant grade copper tubing with internal mirror finishing.

- Unit mounted on C Channels orCastorwheelswith lockable brakes for easy movement..

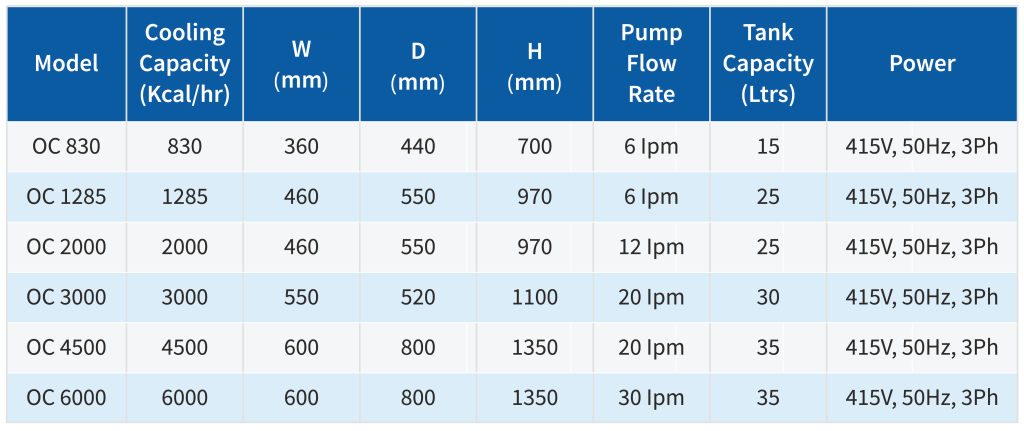

Technical specifications

Applications:

- Metal Cutting-Turning, Machining Centers, Grinding, Honing, Broaching , Drilling, Gear Hobbing, Threading etc..

- General Purpose Machining Equipment

Get In Touch

Interested in our product?

Answer a few short questions and we’ll get in touch with you!

Other cooling Solutions

Explore Our Diverse Product Range